Infrared heating in the warehouse for protection of goods and efficient energy use

With infrared heating in your warehouse, you're choosing a targeted and cost-effective heating method. Warehouses have a different usage profile than production or workspaces. Often, there are fewer employees present, occupancy fluctuates, and the focus is on protecting stored goods. Traditional heating systems are often inefficient in these types of spaces because they have to heat large volumes of air without providing immediate comfort. Infrared heating works efficiently and is therefore very suitable for storage environments.

Specific challenges when heating storage halls

Warehouses are characterized by large surfaces, high ceilings, and fluctuating temperatures. While the space isn't used intensively, it does require a stable indoor climate to protect goods from moisture, cold, or condensation. Convection heating primarily warms the air, which rises quickly and disappears again when the doors are open. Infrared heating, on the other hand, focuses on objects and surfaces, allowing for more manageable temperature and humidity.

How infrared heating works in a warehouse

Infrared heating emits radiant heat that is directly absorbed by floors, walls, shelves, and stored materials. These surfaces slowly release the heat back into the room, creating a more consistent thermal environment without significant fluctuations. The fast response time allows the heating to be switched on only when needed, for example, during work or inspections, without having to continuously heat the entire hall.

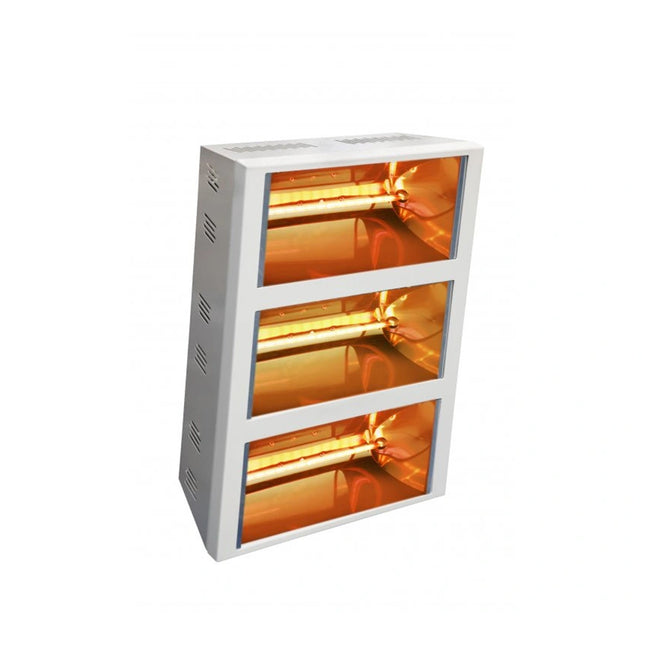

Suitable infrared solutions for warehouses

The ideal infrared solution for a warehouse depends on the layout and height of the space. In high warehouses, ceiling-mounted solutions are often used to distribute heat across the floor. An infrared panel on the ceiling above walkways or work zones provides direct heat without taking up floor space. In warehouses with fixed inspection or processing points, a wall panel be used for added comfort in specific areas. For temporary or seasonal storage, portable infrared heating flexibility without a permanent installation.

Zone heating tailored to storage use

In warehouses, infrared heating is almost always used as zone heating. Only areas where employees are working or goods are being processed are heated. Storage areas where no activity is taking place remain unheated. This significantly reduces energy consumption and prevents unnecessary costs. In warehouses that are part of a larger logistics complex, for example, next to a warehouse or adjacent shed , infrared heating can easily be integrated into a single overall concept.

Protection of goods against cold and moisture

A key purpose of heating in warehouses is to protect goods. Temperature fluctuations and high humidity can lead to condensation, corrosion, or mold growth. Infrared heating helps warm surfaces, keeping them drier and preventing moisture from building up. This is especially relevant when storing materials such as wood, paper, metal parts, or packaged products. By actively heating surfaces, the indoor climate remains more stable and damage and loss of quality are limited.

Comfort and safety for employees

Although employees aren't always present in a warehouse for extended periods, comfort during work is important. Infrared heating provides a pleasant warmth at working height, without drafts or noise. This increases safety and reduces the risk of physical complaints during inspection or loading activities. Because infrared doesn't create air currents, dust is better controlled, which is a major advantage in storage environments.

Main heating or additional solution

In well-insulated warehouses, infrared heating can serve as the primary heating system. In older or open warehouses, infrared is often used as a supplementary solution to increase the perceived temperature and reduce moisture problems. This flexibility makes infrared suitable for a wide range of storage applications. If a warehouse is adjacent to other business spaces, such as a production hall , infrared heating can be easily adjusted per zone.

Capacity and dimensions for storage halls

The required power for infrared heating in a warehouse depends on factors such as surface area, ceiling height, insulation, and the type of goods stored. Warmteshop always performs a customized calculation to determine the correct power and optimal panel placement. This prevents over- or under-sizing. For more background information on efficiency and energy consumption, the article " Is infrared heating economical?" provide valuable insights.

Infrared heating and energy efficiency

Companies are increasingly looking for ways to reduce energy consumption without compromising quality and safety. European publications, such as those available at energy.ec.europa.eu , mention electric radiant heating as an efficient solution for large spaces with variable use. For warehouses, where continuous heating is often unnecessary, infrared fits perfectly within this vision.

Why Warmteshop for warehouse heating?

Warmteshop has specialized in infrared heating since 2006 and has extensive experience heating warehouses and logistics spaces. With over 5,000 infrared panels in stock and warehouses in the Netherlands, Belgium, and Germany, we offer fast delivery and continuity. In our 30+ showrooms , including locations in Antwerp, Ghent, Hasselt, Kortrijk, Brussels, and Culemborg, we showcase solutions tailored to a wide range of storage applications. Our reliability and service are confirmed by independent reviews via Trustprofile .

Warehouse heating as part of a total solution

A warehouse is often part of a larger business process. By cleverly combining infrared heating with other business spaces, a clear and scalable heating system is created. Infrared offers flexibility, control, and reliability, making it easy to grow with changing storage needs.

Back to the complete overview of infrared panels

Warmteshop's full range and discover which solutions are suitable for your warehouse and business environment.