Infrared heating in the warehouse for targeted comfort and lower energy costs

With infrared heating in your warehouse, you're choosing an efficient and future-oriented heating method. Warehouses are often large, high-ceilinged spaces with varying occupancy and limited insulation. Traditional heating systems consume a lot of energy in these spaces because they have to heat large volumes of air that is quickly lost. Infrared heating takes a different approach by providing direct radiant heat to people, shelves, floors, and work areas. This creates comfort where it's needed, without unnecessary waste.

The challenge of heating in warehouses

A warehouse is rarely used continuously like an office or home. There are peak times, varying workloads, and often large doors that open frequently. Warm air heating is inefficient under these conditions because heat rises and dissipates quickly. Infrared heating works independently of air movement and remains effective even in drafts or temperature fluctuations. This makes infrared ideal for logistics areas and storage halls.

How infrared heating works in warehouse environments

Infrared panels emit radiant heat that is directly absorbed by objects and people in the space. In a warehouse, this means that work floors, shelving, and workstations retain heat and release it slowly. This makes the space feel comfortable, even when the air temperature remains lower. Moreover, the heating reacts quickly, which is ideal for warehouses with flexible working hours or shifts.

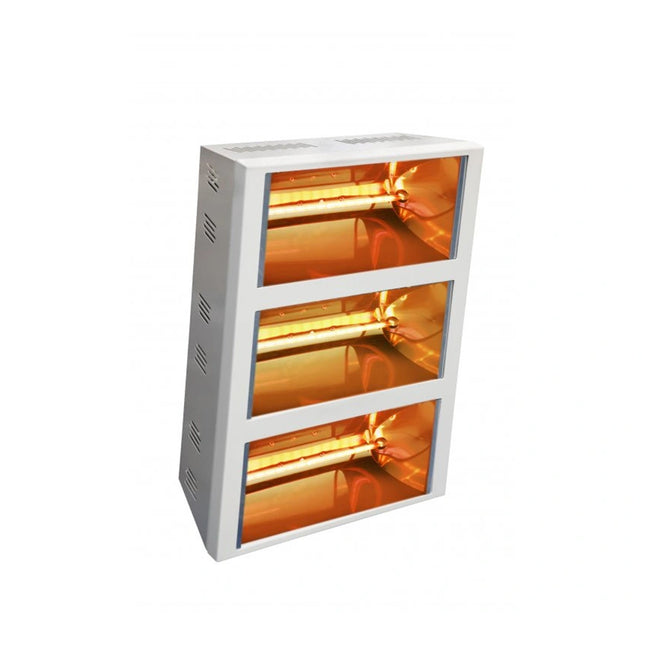

Suitable infrared solutions for warehouses

The right infrared solution depends on the warehouse height and the layout of the work zones. In high warehouses, ceiling-mounted solutions are often used to target specific zones. An infrared panel on the ceiling above loading or picking zones provides direct heat without obstruction. For warehouses with lower ceilings or fixed workstations, a wall-mounted solution be very effective. In temporary zones or seasonal storage, a portable infrared heater maximum flexibility.

Zone heating as the key to energy efficiency

Infrared heating is almost always used as zone heating in warehouses. Only areas where employees are active are heated, such as packing tables, loading stations, or inspection zones. Unoccupied storage areas remain unheated. This approach significantly reduces energy consumption. In warehouses adjacent to other business areas, such as a workshop or office , infrared heating integrates seamlessly into a single, integrated heating plan.

Comfort and productivity in the warehouse

A pleasant working environment directly impacts productivity and safety. Employees who are comfortably warm work more accurately and maintain focus longer. Infrared heating prevents cold hands and stiff muscles without making the space feel stuffy. Because no air is circulated, dust in the warehouse is also better controlled. This is especially relevant in warehouses where packaged products or sensitive goods are stored.

Main heating or support in logistics areas

In well-insulated warehouses, infrared heating can serve as the primary heating system. In older or open warehouses, infrared is often used as supplementary heating, focused on work zones. This flexibility makes infrared suitable for a wide range of logistics applications. In situations where the warehouse is connected to technical rooms or a garage , a uniform infrared solution can ensure consistent comfort and easy management.

Capacity and dimensions for warehouses

The right power output is essential for an effective infrared solution in the warehouse. This depends on factors such as ceiling height, surface area, and the level of insulation. Warmteshop always prepares a customized calculation to ensure the panels provide sufficient heat without being oversized. For companies looking to gain insight into performance and efficiency, the knowledge base offers valuable information, such as the article on comparing infrared heating .

Healthy indoor climate and fewer moisture problems

Warehouses often experience temperature fluctuations and humidity, especially with large doors and goods storage areas. Infrared heating helps keep surfaces dry by directly heating walls and floors. This reduces condensation and lowers the risk of mold or corrosion of materials. Because there is no combustion process, no gases or vapors are released, contributing to a safe and healthy working environment.

Infrared heating and energy policy

More and more companies are critically examining their energy consumption. European publications, such as energy.ec.europa.eu , mention electric radiant heating as an efficient solution for large spaces with varying usage. By cleverly combining infrared with timers and zones, energy consumption can be significantly reduced, especially in warehouses where traditional systems are inadequate.

Why companies choose Warmteshop

Warmteshop has specialized in infrared heating since 2006 and has extensive experience with warehouses and logistics environments. With over 5,000 infrared panels in stock and multiple warehouses in the Benelux and Germany, we guarantee fast delivery and continuity. In our 30+ showrooms , including locations in Antwerp, Ghent, Hasselt, Kortrijk, Brussels, and Culemborg, we showcase solutions specifically tailored to business applications. Our expertise and service are confirmed by independent reviews via Trustprofile .

Warehouse heating as part of a total concept

A warehouse usually doesn't operate in isolation, but rather as part of a larger business premises. Infrared heating can be easily integrated with solutions for other spaces, such as a workshop or logistics office. By coordinating everything within a single infrared concept, an efficient, well-organized, and future-proof heating system is created.

Back to the infrared panels overview

Warmteshop's full range and discover which solutions are suitable for your warehouse and business premises.