Infrared heating in the distribution center for continuity and low energy costs

With infrared heating in your distribution center, you're choosing an efficient solution perfectly suited to high-turnover logistics environments. Distribution centers are characterized by large halls, intensive goods flows, and frequent door openings. Traditional heating systems struggle to provide comfort under these conditions without excessive energy consumption. Infrared heating is targeted and provides direct radiant heat at work height, allowing employees to work comfortably without the need to constantly heat the entire air mass.

Why heating in distribution centers presents specific challenges

In a distribution center, occupancy is constantly fluctuating, and doors are often open for loading and unloading. Convection heating loses a lot of heat in this situation because heated air escapes immediately. Moreover, warm air rises to the ceiling, while the work floor remains cold. Infrared heating is independent of airflows and remains effective, even with constant ventilation and temperature fluctuations. This makes infrared ideal for dynamic logistics environments.

How infrared heating works within logistics processes

Infrared panels emit radiant heat that is directly absorbed by floors, shelves, workstations, and people. In a distribution center, this means that work areas around picking locations and packaging lines retain heat and release it gradually. The heat is noticeable almost immediately after switching on, which is ideal for shifts and fluctuating workloads. This creates a stable perceived temperature without long warm-up times.

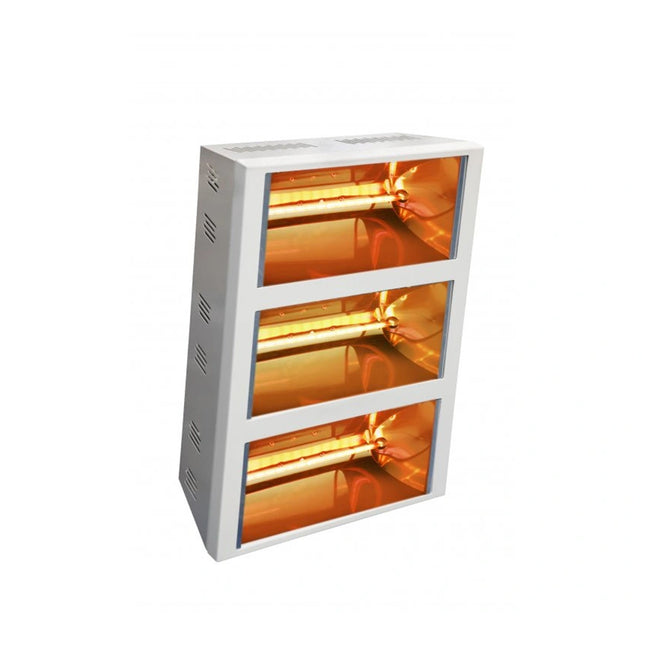

Suitable infrared solutions for distribution centers

The layout of a distribution center requires targeted solutions. High-ceilinged logistics halls often use ceiling solutions to effectively heat large areas. An infrared panel on the ceiling above picking zones or sorting lines provides direct heat without disrupting the logistics process. For fixed workstations along walls, a wall panel provide additional comfort. In seasonal zones or temporary setups, portable infrared heating be deployed flexibly.

Zone heating for maximum efficiency

In distribution centers, infrared heating is almost always used as zone heating. Only the areas where employees are active are heated. Storage areas and transport paths where no one is present remain unheated. This results in significant energy savings compared to traditional systems. In distribution centers that connect with other logistics areas, such as a warehouse or an adjacent warehouse , infrared can easily be integrated into a single heating strategy.

Comfort and productivity on the logistics work floor

A comfortable temperature is essential for productivity and safety. In cold conditions, physical complaints increase and concentration decreases. Infrared heating provides pleasant warmth at working height without drafts or noise. Because the air isn't actively moved, dust is better controlled. This is beneficial in distribution centers where speed, accuracy, and order are paramount.

Main heating or support in distribution centers

Depending on the level of insulation, infrared heating can serve as the primary heating source or as a supplementary solution. In modern, well-insulated distribution centers, infrared can meet all heating needs. In older buildings, infrared is often used to provide comfort in workspaces while minimizing primary heating. This flexibility makes infrared suitable for a wide range of logistics scenarios.

Capacity and dimensions tailored to logistical use

Determining the correct output is crucial for an effective infrared solution in a distribution center. Factors such as ceiling height, open doors, floor space, and staff density play a role. Warmteshop always prepares a customized heat calculation to determine the optimal output and the correct panel placement. For additional insights into yield and efficiency, the article on comparing infrared heating provide additional context.

Control of moisture and indoor climate

Distribution centers often experience temperature differences between indoors and outdoors, which can cause condensation. Infrared heating helps keep surfaces dry by directly heating floors and walls. This limits moisture problems and reduces the risk of damage to packaging or stored goods. The even radiant heat contributes to a stable and manageable indoor climate.

Infrared heating and energy policy

European energy publications highlight electric radiant heating as an efficient solution for large buildings with variable occupancy. Information platforms like energy.ec.europa.eu explain how targeted heating and zone heating can reduce energy consumption. For distribution centers, infrared is therefore an excellent fit for sustainability goals and cost control.

Why logistics companies choose Warmteshop

Warmteshop has been a specialist in infrared heating since 2006 and supports logistics companies in a wide range of sectors. With over 5,000 infrared panels in stock and logistics capacity in the Netherlands, Belgium, and Germany, we can respond quickly, even to larger projects. In our 30+ showrooms , including locations in Antwerp, Ghent, Hasselt, Kortrijk, Brussels, and Culemborg, we demonstrate practical setups tailored to logistics applications. Our reliability and expertise are confirmed by independent reviews via Trustprofile .

Distribution center heating as part of a total concept

A distribution center functions as a link within a larger logistics network. Infrared heating is easily integrated with other business spaces and adapts to changes in logistics processes. By choosing targeted heating solutions, you create a future-proof heating system that combines flexibility, comfort, and efficiency.

Back to the infrared panels overview

Warmteshop's full range and discover which solutions are best suited to your distribution center and logistics environment.