Infrared heating in the warehouse for targeted heat and maximum efficiency

With infrared heating in your warehouse, you choose a practical and energy-efficient way to heat large, open spaces. Warehouses are often used for storage, production, assembly, or logistics operations and are characterized by high ceilings, large doors, and varying occupancy. Traditional heating systems lose a lot of heat in such spaces and result in high energy costs. Infrared heating works fundamentally differently and is therefore ideal for warehouses where targeted comfort is more important than heating the entire air mass.

Why traditional heating falls short in warehouses

Warehouses are usually poorly to moderately insulated and experience significant air movement through loading and rolling doors. Convection heating primarily warms the air, which rises immediately and is quickly lost. As a result, working heights often remain cold, while energy consumption is high. Infrared heating addresses this problem at its core by transferring heat directly to people, machines, floors, and materials. This creates comfort where work is actually being done, without waste.

The operation of infrared heating in a warehouse

Infrared heating uses radiant heat to directly warm objects and people. In a warehouse, this means that work areas, floors, and machinery absorb heat and gradually release it into the environment. The heat is noticeable almost immediately after switching on and remains stable, even when doors are opened frequently. This makes infrared ideal for warehouses with varying workloads and irregular occupancy.

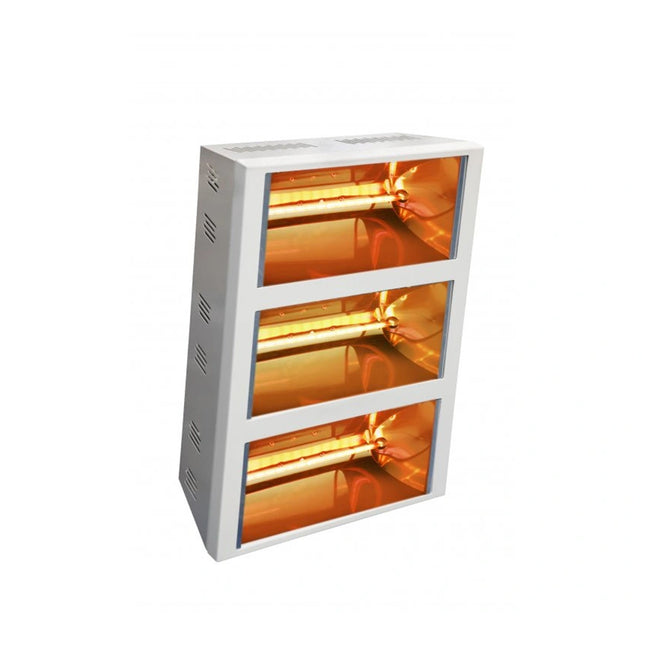

Suitable infrared solutions for warehouses

Choosing the right infrared system depends on the height and layout of the warehouse. High-rise warehouses often opt for powerful ceiling solutions that heat specific zones. An infrared panel on the ceiling above work or circulation areas provides direct heat without taking up floor space. In warehouses with fixed workstations, a wall panel be an efficient solution for creating targeted comfort. For temporary or flexibly designed zones, a standing infrared heater be easily deployed and moved.

Zone heating as a basic principle

Infrared heating in warehouses is almost always used as zone heating. Only areas where employees are actually present are heated. Storage areas, walkways, or unused parts of the warehouse remain unheated. This approach results in significant energy cost savings and makes infrared particularly suitable for large industrial buildings. In warehouses connected to other business spaces, such as a warehouse or workshop , infrared is a logical fit within a single, integrated heating concept.

Comfort and safety in the warehouse

A comfortable temperature directly impacts safety and productivity. Cold warehouses lead to fatigue and increase the risk of errors. Infrared heating creates warm work zones without drafts or noise. Because no air is circulated, dust is better controlled, which is important in production or storage environments. Furthermore, infrared does not involve an open flame or combustion, making the system safe for use in industrial applications.

Infrared as main or supplementary heating

In well-insulated warehouses, infrared heating can be used as the primary heating system. In older or open-plan structures, infrared is often used as supplementary heating to increase comfort in workplaces. This flexibility allows for a customized solution for each warehouse. If the warehouse is adjacent to other spaces, such as a garage or office area, infrared can easily be adjusted to each individual room.

Capacity and efficiency in pilots

The required power for infrared heating in a warehouse depends on several factors, including ceiling height, surface area, and insulation level. Warmteshop always performs a heat calculation based on your specific situation. This ensures optimal panel positioning and prevents over- or undersizing. For additional insight into performance and efficiency, the knowledge base offers valuable in-depth information, such as in the article " Is infrared heating economical ?"

Healthy indoor climate and less condensation

Warehouses often experience condensation, especially with temperature fluctuations and humid outdoor air. Infrared heating helps keep surfaces dry by directly heating floors and walls. This reduces moisture problems and minimizes the risk of corrosion of materials and machinery. Because infrared doesn't create air currents, the indoor climate remains stable and comfortable for employees.

Infrared heating and the European energy vision

In European publications on energy efficiency, electric radiant heating is increasingly being mentioned as a solution for large, irregularly used spaces. Platforms like energy.ec.europa.eu explain how direct electric heating can contribute to more targeted energy use. For warehouses, where traditional heating is often inefficient, infrared fits perfectly within this vision.

Why Warmteshop for warehouse heating?

Warmteshop has specialized in infrared heating since 2006 and has extensive experience with industrial applications such as warehouses and industrial buildings. With over 5,000 infrared panels in stock and warehouses in the Netherlands, Belgium, and Germany, we offer fast delivery and technical support. In our 30+ showrooms , including locations in Antwerp, Ghent, Hasselt, Kortrijk, Brussels, and Culemborg, we demonstrate practical installations and offer expert advice. Our reliability is confirmed by independent reviews on Trustprofile .

Lead heating as part of a future-proof overall plan

A warehouse is often part of a larger business process. By cleverly combining infrared heating with other areas within the building, a clear and efficient heating system is created. Infrared offers flexibility, scalability, and control, making it easy to grow with changing business needs.

Back to the complete overview of infrared panels

Discover all the solutions within Warmteshop's range of infrared panels and create a heating concept that perfectly suits your warehouse.