Infrared heating in the industrial hall for efficient comfort and control

With infrared heating in your industrial space, you're choosing a heating solution that perfectly complements modern business operations. Industrial spaces vary widely in function and use, from production and assembly to storage, logistics, and service activities. What all these spaces have in common is that traditional heating systems are often inefficient due to high ceilings, fluctuating occupancy, and frequent door openings. Infrared heating provides targeted radiant heat at working height and prevents energy loss by heating unused air layers.

Why industrial buildings have different heating needs

A warehouse is rarely fully occupied at all times. Work takes place in specific zones, while other parts of the warehouse are rarely used. Convection heating warms the air throughout the entire space and causes warm air to rise toward the ceiling. Infrared heating works differently, directly warming people, workstations, and objects. This creates comfort where it's needed, without having to heat the entire warehouse.

The operation of infrared heating in industrial halls

Infrared panels emit long-wave radiation that is absorbed by surfaces such as floors, walls, machines, and workbenches. These surfaces then gradually release the heat into the room. In a factory, this results in a stable perceived temperature, even with open doors or fluctuating outdoor temperatures. Because the heat is quickly noticeable, the heating can be used flexibly during varying working hours or shifts.

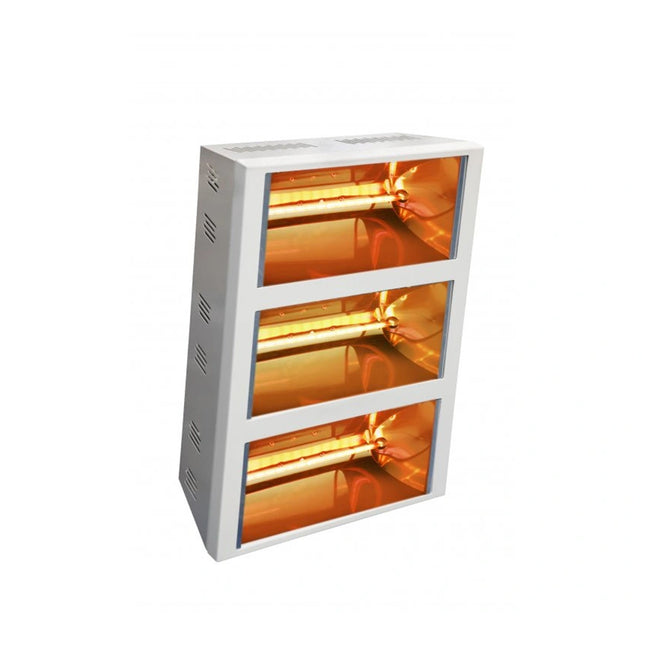

Suitable infrared solutions for industrial halls

The ideal infrared solution depends on the layout and height of the production hall. In high halls, ceiling-mounted solutions are often used to effectively heat zones. An infrared panel on the ceiling above workstations or production lines provides direct heat without taking up space. In halls with fixed workstations along walls, a wall panel provide targeted heat. For flexible or temporary applications, a standing infrared heater a solution.

Zone heating for optimal energy efficiency

Infrared heating is almost always used as zone heating in industrial halls. Only the zones where employees are active are heated. This prevents unnecessary energy consumption in storage or traffic zones. Industrial halls with multiple functions, such as a combination of assembly and logistics , can easily be coordinated per zone within a single central heating plan using infrared.

Comfort, safety and working conditions

A stable and comfortable indoor climate in the production hall contributes to safety and work quality. Cold conditions lead to fatigue, reduced concentration, and a higher risk of errors. Infrared heating provides even heat without drafts or noise. Because there is no combustion process, no flue gases or fumes are released, contributing to a safe working environment.

Main heating or additional solution

Depending on the insulation level and the intended use, infrared heating can serve as the primary heating system or supplement an existing system. In modern, well-insulated industrial buildings, infrared can meet all heating needs. In older buildings, infrared is often used to create comfort in the workplace while limiting the primary heating needs. This flexibility makes infrared suitable for a wide range of business environments.

Capacity and custom calculations for industrial buildings

Determining the correct output is essential for an effective infrared solution in your industrial building. Factors such as ceiling height, surface area, insulation, and the type of work play a significant role. Warmteshop always prepares a customized heat calculation to determine the optimal output and best panel placement. For more in-depth insights into efficiency and performance, the article " Comparing infrared heating" provide valuable background information.

Control of moisture and condensation

Condensation can occur in industrial buildings due to temperature fluctuations and ventilation. Infrared heating helps keep surfaces dry by directly heating walls and floors. This reduces moisture problems and minimizes the risk of corrosion or damage to materials and machinery. The result is a more stable indoor climate and lower maintenance costs.

Infrared and sustainable energy policy

More and more companies are focusing on energy efficiency and sustainability. European energy publications, such as those available at energy.ec.europa.eu , mention electric radiant heating as an effective solution for large spaces with variable occupancy. By combining infrared with smart control and, potentially, renewable energy sources, the system fits perfectly within modern sustainability strategies.

Why companies choose Warmteshop

Warmteshop has specialized in infrared heating since 2006 and supports companies in a wide range of sectors. With over 5,000 infrared panels in stock and warehouses in the Netherlands, Belgium, and Germany, we guarantee fast delivery and continuity. In our 30+ showrooms , including locations in Antwerp, Ghent, Hasselt, Kortrijk, Brussels, and Culemborg, we demonstrate practical setups tailored to industrial buildings. Our expertise and service are confirmed by independent reviews via Trustprofile .

Industrial hall heating as part of a future-proof total concept

A production hall is often part of a larger business process. Infrared heating can be easily integrated with other business spaces and grows with changes in layout or production capacity. By choosing infrared, you create a flexible, scalable, and energy-efficient heating system that matches the ambitions of modern businesses.

Back to the infrared panels overview

View Warmteshop's complete range of infrared panels and discover which solutions best suit your industrial building.