Infrared heating in the assembly hall for precision work and continuous comfort

With infrared heating in your assembly hall, you create a stable and comfortable work environment where accuracy and efficiency are paramount. Assembly halls differ from other industrial spaces because employees often work in fixed positions for extended periods, performing precision work. Temperature fluctuations or cold workstations directly impact concentration, product quality, and speed. Infrared heating delivers targeted radiant heat precisely at the work height and prevents energy loss by heating unused air layers.

Why assembly halls have specific requirements for heating

In assembly halls, a consistent temperature is essential. Employees often work with small parts, tools, and assembly lines, where cold hands or an unpleasant climate reduce productivity. Traditional air heating warms the space slowly and unevenly, while warm air rises and remains trapped under the ceiling. Infrared heating addresses this problem at its core by providing direct heat to people, work tables, and machines.

The operation of infrared heating in assembly environments

Infrared panels emit long-wave radiation that is directly absorbed by objects and people in the space. In an assembly hall, this means that workbenches, floors, and materials retain heat and release it gradually. This creates a constant perceived temperature around the workspace. The rapid warm-up time also makes the system suitable for shift work and varying production schedules, without lengthy start-up times.

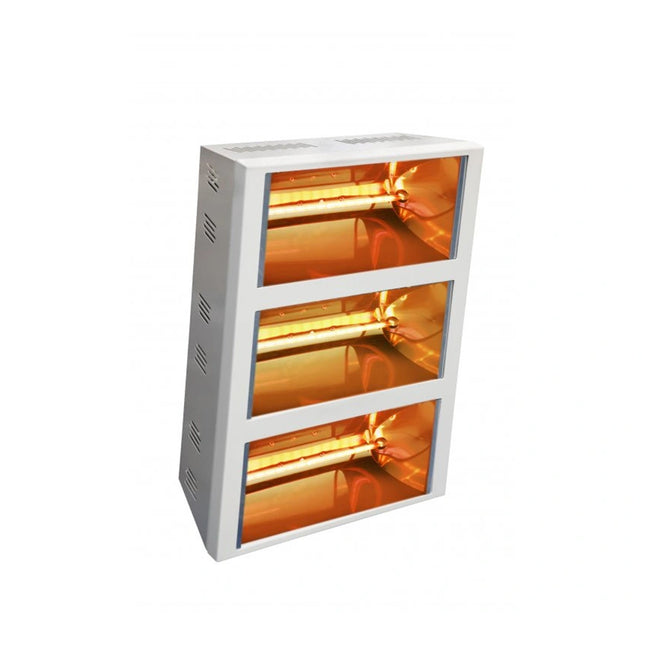

Suitable infrared solutions for assembly halls

The choice of an infrared system for an assembly hall depends on the working height and layout of the hall. In halls with sufficient ceiling height, an infrared panel on the ceiling above assembly lines is an efficient solution. This provides even heat without obstructing the work floor. For specific workstations along the walls, a wall panel portable infrared heater can be used to provide temporary heat where needed.

Zone heating tailored to assembly processes

Infrared heating in assembly halls is almost always used as zone heating. Only the areas where work is actually being done are heated. This keeps energy consumption low while maintaining high comfort. Assembly halls that are part of a larger production process, for example, next to a production hall or an adjacent warehouse , can easily be integrated into a single, cohesive heating system using infrared.

Comfort, focus and product quality

A comfortable temperature directly impacts the focus and accuracy of assembly workers. Infrared heating prevents cold hands and ensures a stable thermal environment without noise or airflow. This promotes concentration and reduces the risk of errors. Moreover, even heat contributes to consistent material conditions, which can be important for precision assembly or sensitive products.

Main heating or support in assembly halls

Depending on the construction and insulation, infrared heating can serve as the primary heating system or as a supplementary solution. In modern, well-insulated assembly halls, infrared can fully meet the heating needs. In older halls, infrared is often used as supplementary heating to increase workplace comfort while limiting primary heating needs. This flexibility makes infrared suitable for a wide range of assembly environments.

Power and custom calculation

The required capacity for infrared heating in an assembly hall depends on factors such as surface area, ceiling height, insulation, and the number of workstations. Warmteshop always performs a customized calculation to determine the optimal capacity and correct placement. This prevents installation of either too much or too little capacity. For more information on efficiency and systems, the article " Comparing infrared heating" additional insights.

Healthy indoor climate and less dust movement

In an assembly hall, a clean and stable indoor climate is essential. Infrared heating doesn't cause air circulation and therefore limits dust movement. This is beneficial for employees and for products that are sensitive to dust or temperature fluctuations. Furthermore, direct heating of surfaces helps reduce condensation, contributing to a cleaner and more reliable work environment.

Infrared heating within European energy visions

Electric radiant heating is increasingly being cited in European energy policy documents as an efficient solution for industrial spaces with specific heating needs. Information platforms such as energy.ec.europa.eu emphasize that targeted heating and zone heating can contribute to lower energy consumption per production unit. Infrared is an excellent solution for assembly halls.

Why Warmteshop for assembly hall heating?

Warmteshop has specialized in infrared heating since 2006 and has extensive experience with industrial applications such as assembly halls. With over 5,000 infrared panels in stock and warehouses in the Netherlands, Belgium, and Germany, we can deliver quickly and collaborate on customized solutions. In our 30+ showrooms , including locations in Antwerp, Ghent, Hasselt, Kortrijk, Brussels, and Culemborg, we showcase solutions tailored to a wide range of industrial situations. Our expertise and service are confirmed by independent reviews via Trustprofile .

Assembly hall heating as part of a total concept

An assembly hall is often part of a larger production and logistics process. Infrared heating is easily integrated with other business areas within the building and offers flexibility for changing layouts or production volumes. By strategically deploying infrared, you create a future-proof heating system that grows with your organization.

Back to the complete overview of infrared panels

Warmteshop's extensive range and optimally tailor the heating to your assembly hall.